Seamless Universal Connectivity

The Harvestree module features four universal inputs for external sensors. Configurable via the USB-C port, these inputs allow the system to seamlessly interface with a wide range of industrial sensor types. By powering and connecting up to four distinct sensors simultaneously, the module delivers exceptional measurement flexibility and versatility for diverse industrial applications.

Test Harvestree in the Real World – With Zero Development Effort

Frequently asked questions

Here are some common questions about Harvestree product

The module is self-powered using a patented thermal energy harvesting solution. It works by converting waste heat from the surface it is mounted on—whether the surface is hot or cold relative to the ambient air—into the electrical energy needed to run the sensors and radio transmission

The core benefits are Limitless Simplicity and cost savings. Since it contains no batteries or wires, it offers zero maintenance for 15+ years. This design avoids the cost and complexity of cable installation and eliminates the significant operational costs associated with periodic battery replacement in large or isolated fleets

The 4 external inputs offer high compatibility with industrial sensors. Supported sensor types include: Temperature probes (Any Pt1000 probe or K-type thermocouple); Vibration sensors; Analog signals (ranging from -500 mV/+500 mV or 0 to 3V); I2C sensors (for parameters like pressure, humidity, moisture, gas, light, and distance); and Dry contact inputs (for monitoring equipment status or power supply). Specialized sensors like strain gauges and displacement gauges are also supported

One Harvestree node is engineered to seamlessly interface with up to 4 external sensors using waterproof industrial connectors. This configuration is referred to as "4 in 1". It also includes a built-in Pt1000 temperature sensor embedded within the aluminum baseplate for continuous temperature measurement of the surface

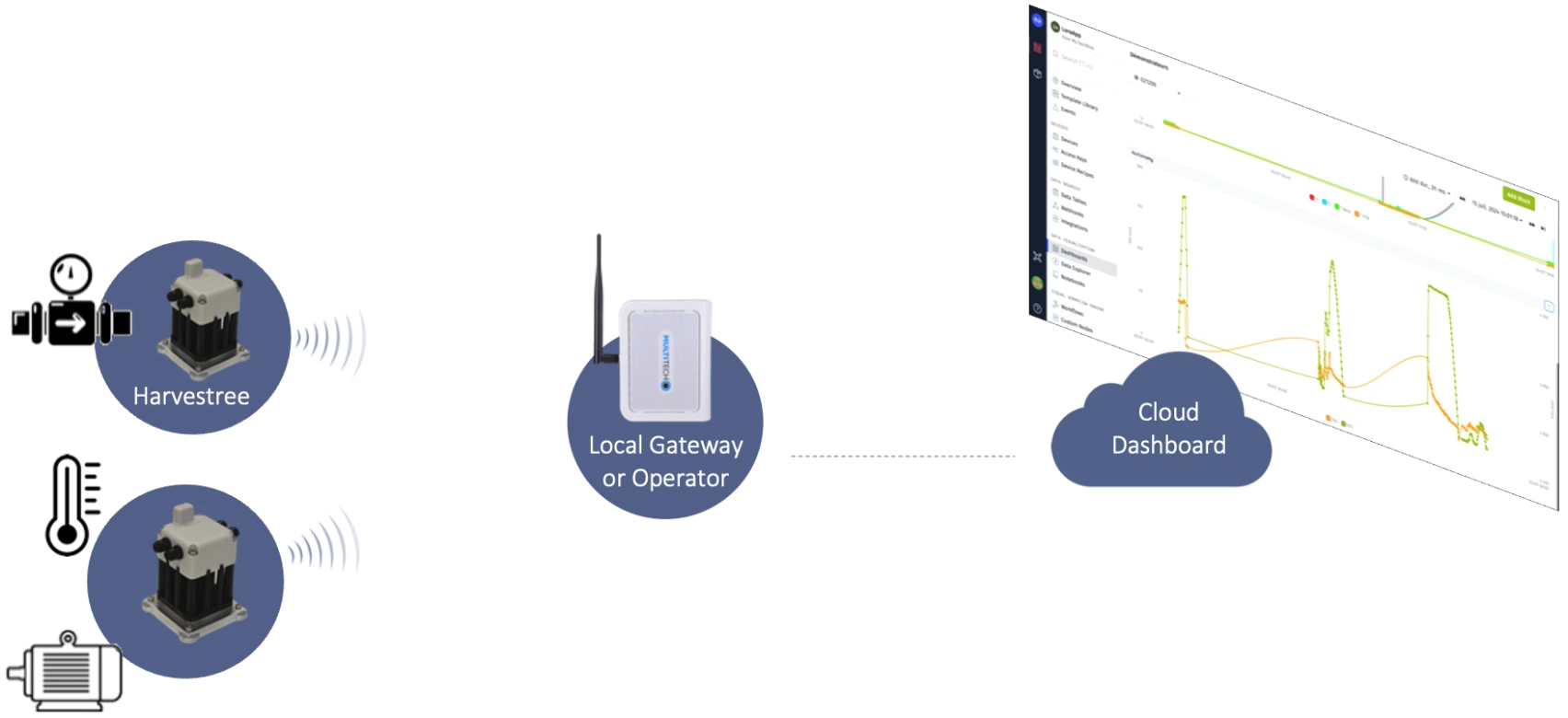

Harvestree primarily uses LoRaWAN (Long-Range Wide-Area Network), offering extended connectivity and bidirectional communication. The robust energy generation supports high-frequency transmission (less than 1 minute) and is ready for integration with other protocols, including 2.4 GHz, Bluetooth, NB-IoT, LTE-M, and 5G

It is highly suited for heavy industries such as steel, cement, glass, petrochemicals, and metallurgy (e.g., Aluminum Electrolysis monitoring). It is also effective in monitoring critical infrastructure in Railway (tracks, catenary, signaling) and Electrical Transmission & Distribution/Smart Grid (transformers, busbars, substations), as well as rotating machine monitoring (vibration analysis for pump health)

Harvestree offers a sustainable and eco-friendly approach. It conserves natural resources by eliminating the need for lithium battery production. The module actively recycles waste heat ("fatal heat") from industrial processes. Over its 15-year lifespan, one Harvestree module can harvest the equivalent power of 20 to 40 primary batteries

The module supports a wide operating temperature range. The aluminum baseplate, which contacts the heat source, can operate from -80°C up to 180°C (standard reference), and can be installed on surfaces up to 350°C (with a specific accesory). The internal electronics can operate from -20°C up to 80°C