Process temperature drift monitoring

In many industrial processes, small and progressive temperature deviations are often the earliest sign of an upcoming issue before throughput, energy consumption, or product quality is impacted. By connecting a standard PT1000 or thermocouple probe to a Harvestree node, teams get continuous temperature trending and real-time alerts on subtle drift. This enables early corrective actions (adjustments, checks, planned maintenance), preventing off-spec production, waste, and reactive interventions

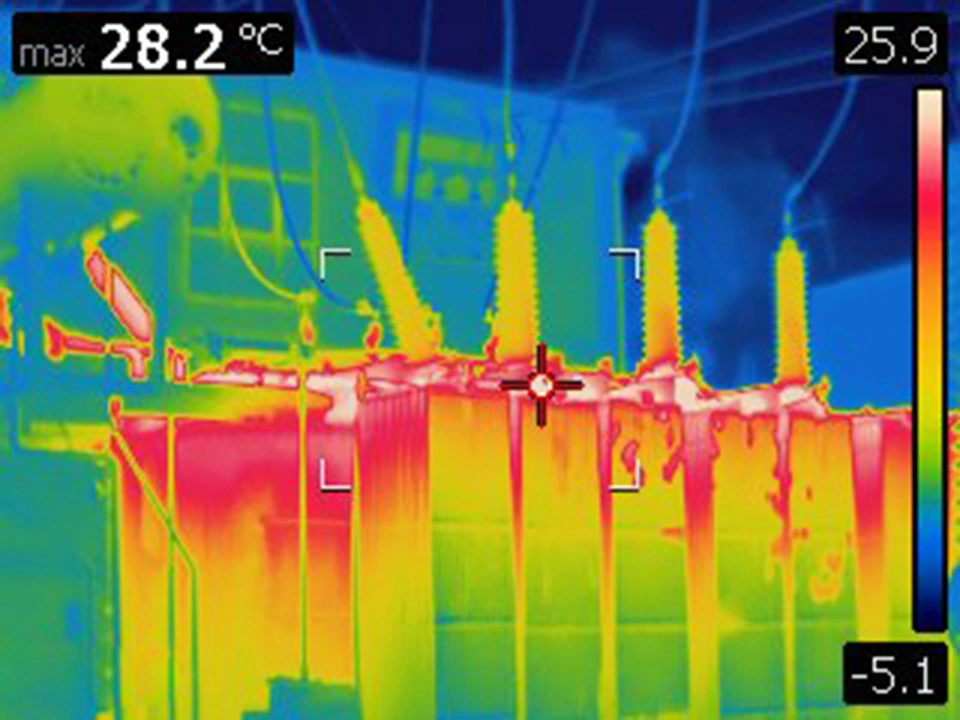

Hot-spot monitoring on power distribution assets

In electrical infrastructure, localized hot spots on busbar joints, breaker contacts, transformer terminations, or cable lugs are common precursors to insulation degradation and critical incidents. A simple PT1000 or thermocouple probe placed near the joint and connected to the Harvestree wireless, battery-free node provides continuous thermal monitoring without wiring constraints or battery maintenance. Operations teams can detect gradual temperature rise under normal load, correlate events with operating conditions, and trigger targeted inspections or corrective tightening/replacement—improving safety, extending asset life, and avoiding costly emergency outages.